Railroads are an indispensable part of the supply chain when transporting both bulk shipments and intermodal containers. Compared to truck – its main competitor – train is cheaper (in the US it’s 4 cents vs 20 cents per ton-mile), more efficient (the record-breaking train was 682 cars and 4.5 miles long carrying 82,000 metric tons of ore), and more sustainable (one ton of freight can be moved over 470 miles on just a single gallon of diesel fuel).

So today, for example, the US freight rail network comprises nearly 140,000 miles of track, moving about one-third of all US exports and around 40 percent of long-distance freight volume.

Out of approximately 630 private freight rail companies in the US, the 7 “Class I” railroads account for 68 percent of all track mileage (and 94 percent of revenue). All the rest are smaller, regional/short-line operators that connect industries to supply sources (e.g., a power plant and a coal mine) or link-up companies and small towns to larger railroad lines.

No matter how many carloads you move, how many trains you operate, and whether you own or lease your rolling stock, you want to keep it operating as efficiently as possible. For that, you need complete control of your assets and full visibility into related business processes. So, let’s talk about how modern technology can help you manage your rail fleet.

Watch how AI transforms the rail industry

What is fleet management in railways?

Rail fleet management is a set of activities aimed at controlling the condition and performance of rail assets. The ultimate goal is to increase their utilization efficiency, reduce downtime, and deliver the maximum ROI.

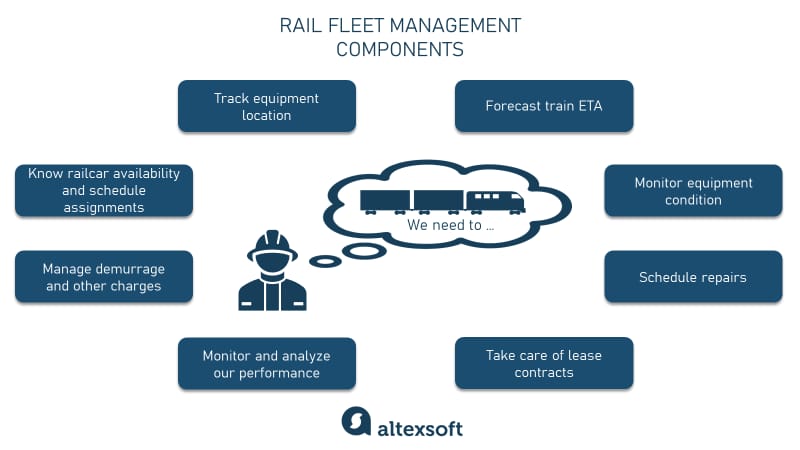

Rail fleet management as an administrative process is important for all the parties involved in rail freight transportation that deal with rolling stock, i.e., railroads, shippers, leasing companies, and logistics service providers. Most businesses mainly focus on asset tracking and maintenance, but there are more activities involved. We can outline the following key aspects that rail fleet management embraces.

Rail fleet management main components

Rolling stock tracking. All stakeholders want to know where their equipment and/or shipments are. One of the ways is getting location information manually from the railroad website. If your long-haul transportation is managed by several rail companies, you have to gather data from different sources.

ETA forecasting. Understanding when exactly the train is expected to arrive is of the same importance for shippers and other supply chain stakeholders. Most Class I railroads have adopted PSR (precision scheduled railroading) so that freight trains operate on a consistent schedule. It helps a lot, but things still go unplanned sometimes. And for smaller railroads that don’t have stable timetables, ETA calculation is an essential part of a fleet manager's daily routine.

Asset condition monitoring. All railroads utilize a growing number of wayside detectors, while rolling stock becomes more and more equipped with onboard sensors. Fleet managers have to carefully monitor all the readings to promptly react in case any anomalies are detected.

Scheduling and conducting maintenance activities. Preventive maintenance with its planned routine servicing has become a standard approach in the rail industry. But it requires careful scheduling to balance necessary repairs and inevitable downtime. In addition, if you are responsible for maintenance activities, there’s a lot of additional processes, i.e., task assignments, parts inventory management, staff scheduling, documentation, etc.

Monitoring railcar availability and creating assignment schedules. Fleet managers must always know the availability status of rolling stock and create schedules of future workloads. It’s crucial to keep just the right number of assets to meet transportation demand and freight requirements. At the same time, you should avoid bloating your fleet to minimize storage/demurrage charges and other expenses.

Managing demurrage and other accessorial charges. Speaking of demurrage, it’s another aspect that has to be carefully monitored. If you operate a railroad, you need to accurately calculate demurrage and other accessorial charges that have to be compensated. If you’re a shipper or carrier that was charged, well, the payment is inevitable, but you still need to keep records in case any disputes arise (and for analytical purposes too). For that, having precise tracking data is a must.

Managing lease contracts. If you deal with railcar leasing, you have to organize your contracts and keep them up to date, watch for expiration dates and required renewals, and so on.

KPI monitoring and analytics. Strategic decisions are most effective when they are based on data and analytics. Performance metrics have to be consistently monitored to uncover your company’s problem areas and development opportunities.

As you can see, fleet management is a complicated, multi-component business process that requires careful resource coordination and continuous control to accomplish the company’s strategic objectives.

Your own business challenges depend on your part in this game, your current stage of digitization, and whether you own or lease rail equipment. Luckily, modern technologies can take some burden off the fleet manager’s shoulders by automating a number of daily operations. But before talking about software systems, let’s discuss the hardware part.

Hardware and technologies in rail fleet management

Nowadays, the rail industry heavily relies on modern technologies for safety and tracking. It widely adopts various sensors, scanners, detectors, and other smart devices that help replace lengthy and error-prone human checks.

Here are some nifty gadgets that the rail industry takes advantage of.

Rail defect detectors

Rail defect detectors are devices with sensors that scan passing trains and identify various faults or defects. These devices are installed by the side of the railroad track (wayside defect detectors) and/or integrated into the tracks. As the train passes, some defect detectors automatically report the axles/wheels/bearings condition and any found problems over the radio to alert the train crew.

In these sensors, a wide range of technologies is used, from infrared beams to lasers to acoustic analysis. Some of the industry-popular sensors are

- hotboxes or hot bearing detectors,

- hot wheel detectors,

- wheel profile systems,

- acoustic bearing detectors,

- bogie performance detectors or bogie geometry monitors,

- dragging equipment detectors,

- rail brake monitors,

- weigh-in-motion sensors or imbalance detectors (those are especially useful to make sure double-stacked containers aren’t shifted or loose),

- high car or shifted load detectors (sometimes combined with wide-load detectors), and so on.

Hot Box detector. Source: ApnaTech

Cameras

Besides benefiting from these widespread sensors, railroads keep innovating and investing in newer, more efficient equipment inspection technologies. For example, Union Pacific, the second largest US railroad, has developed Machine Vision – a system based on image recognition technologies that can remotely scan a mile-long train moving at 70 mph. Specialized cameras collect thousands of images per second which are then analyzed by a series of algorithms to identify anomalies – all that in a blink of an eye.

Onboard sensors

In addition to external sensors installed in or near the rail tracks, data loggers and other smart devices can be attached to different parts of locomotives or railcars to record important measurements (temperature, vibration, noise, etc.) from inside the train during operation. Say, the Norfolk Southern Railway (another tech-savvy Class I railroad) locomotives are equipped with onboard sensors that stream more than 200 readings and diagnostic elements in real-time and support predictive servicing.

Tracking technologies: RFID tags, GPS, etc.

In the US, a so-called automatic equipment identification (AEI) system based on RFID technology is widely implemented, with thousands of readers installed along tracks and millions of tags on the rolling stock (since 1994, AAR has required all locomotives and cars to have data tags).

GPS-based telematics systems are also frequently utilized for train tracking. In tunnels where the satellite signals are lost, beacons and readers that utilize the ultra-wideband (UWB) or Bluetooth Low Energy (BLE) data-transmitting technologies are often used to complement GPS.

IoT and telematics in rail

All the devices we described serve as a source of massive amounts of data. When connected to cloud-based storage and processing solutions, they create the Internet of Things (IoT) infrastructure. This interrelated network of connected devices not only supports immediate monitoring and tracking, but also enables data collection, storage, and processing, leading to generation of actionable insights and valuable analytics results.

Telematics is one of the examples of IoT implementation in the transportation industry – and rail in particular. Telematics devices help monitor vehicle location and activity, diagnose engine faults, and collect other crucial performance information.

Now that we’ve described which technologies are currently utilized, let’s talk about how exactly they can make your life easier.

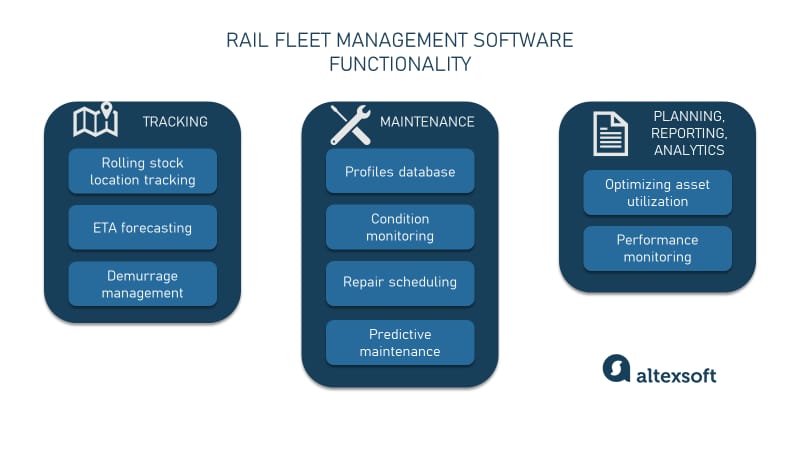

Rail fleet management software features

Tracking and ETA forecasting in railway

Tracking traditionally refers to knowing the exact location of an asset, shipment, or whatever. However, in the rail industry, a robust track and trace system allows managers to go beyond that and obtain actionable information on the status and condition of their rolling stock. That, in turn, leads to optimizing asset utilization, balancing assignments, and more convenient scheduling.

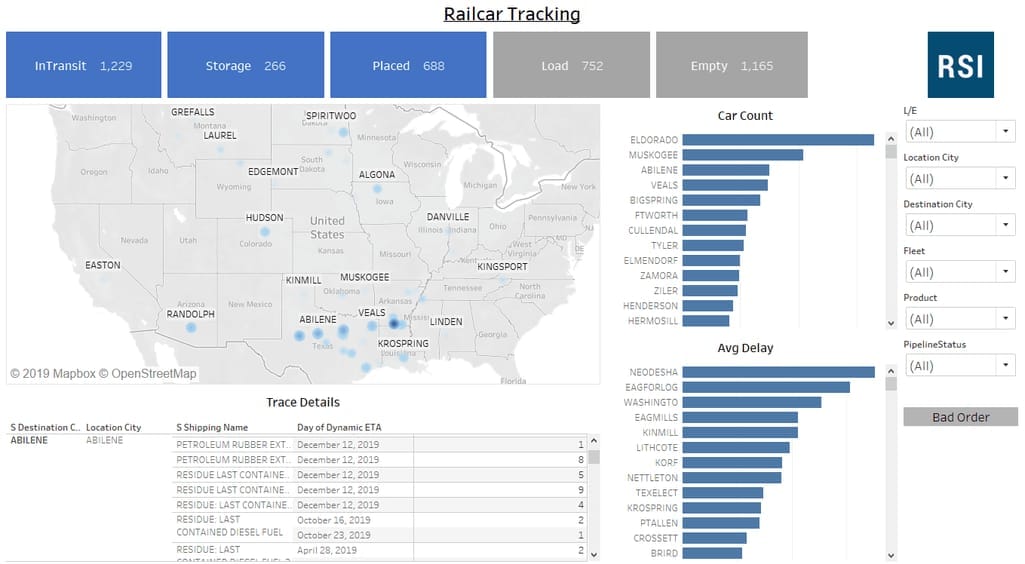

Railcar and shipment tracking

Tracking software allows fleet managers to see the equipment location in real-time, often complemented with a map-view. It also becomes convenient to monitor mileage, availability, delays, arrivals/departures and other important status updates via dashboards and customized tables.

Railcar tracking software interface. Source: RSI Logistics

ETA forecasting

As we’ve mentioned above, PSR (precision scheduled railroading) brought some order into freight transportation. But when disruptions happen, you need a backup solution. So, having real-time tracking data, software can make accurate, dynamic ETA predictions.

Demurrage management

Demurrage charges, rules, and policies vary across railroad companies. In a perfect world, once you know all the regulations, you can optimize the flow of cars and align them with a facility capacity.

In reality, again, things often go wrong, delays happen, and charges are accrued. To avoid overpaying, you have to be in control and know exactly what you pay for. Tracking software will let you know when cars are shipped, constructively placed, actually placed, released, and how many days are held. You’ll also be able to calculate and monitor storage costs.

If you are a railroad operator, the system will automatically calculate demurrage charges considering your company daily rates and credit days and create invoice-ready reports.

Another benefit is that you’ll have a complete historical record of shipping cycles and railroad service issues (e.g., delayed cars, switching failures, cars ordered but not placed) in case any disputes arise, as well as for future analysis.

How to track rail equipment?

As we said above, all the railcars (at least in the US) have attached tracking devices. Now, the question is how to get ahold of this data?

To track your assets, you basically have three main options (except for just visiting the railroad website and checking the rail cars’ location manually).

Get tracking software. Most fleet management software providers offer asset tracking functionality, ETA calculation, demurrage management, and other handy features out of the box. Some vendors also sell their own telematics devices for an easier connection and gathering additional data.

Connect to a data provider. Railinc, subsidiary of the Association of American Railroads (AAR) and the official industry information source, suggests getting track and trace data either from Steelroads (for sponsored users who are also waybill parties) or RailSight. You can integrate a data feed via API, EDI, and other connectivity formats. There are other third-party tracking data providers, e.g., Geoforce or Trusted.

Build a custom IoT network. You can build a connected IoT infrastructure and collect information directly from telematics devices, RFID readers, and so on. It’s more costly and complicated but you’ll have a fully customized product tailored to your business needs.

Rail fleet maintenance

Just like in any other industry, timely maintenance is crucial for safe and efficient rail equipment functioning. It also allows for avoiding unexpected and costly breakdowns that result in downtime, financial losses, and delayed shipments.

Fleet management software usually has maintenance-related modules that help handle health monitoring, service scheduling, failure history, spare parts usage, and other related processes, as well as documentation. It can also be a standalone platform which is often referred to as a computerized maintenance management system (CMMS).

Equipment profiles

Fleet management software serves as a centralized database for all your assets. It’s convenient to have profiles of every piece of equipment for easy reference. They include trip information, mechanical details, service dates and costs, and much more. Many platforms also have an integration with UMLER – the main industry database in North America – for easy access to all rail equipment characteristics.

Condition monitoring and alerts

As we said above, there’s a lot of sensors and detectors already implemented on major railroads and on the rolling stock that help identify failures or alert of potential breakdowns. However, if you have specialized software, you can monitor your rolling stock health in one system. You’ll receive important condition updates and notifications in case anomalies are detected or breakdowns are anticipated.

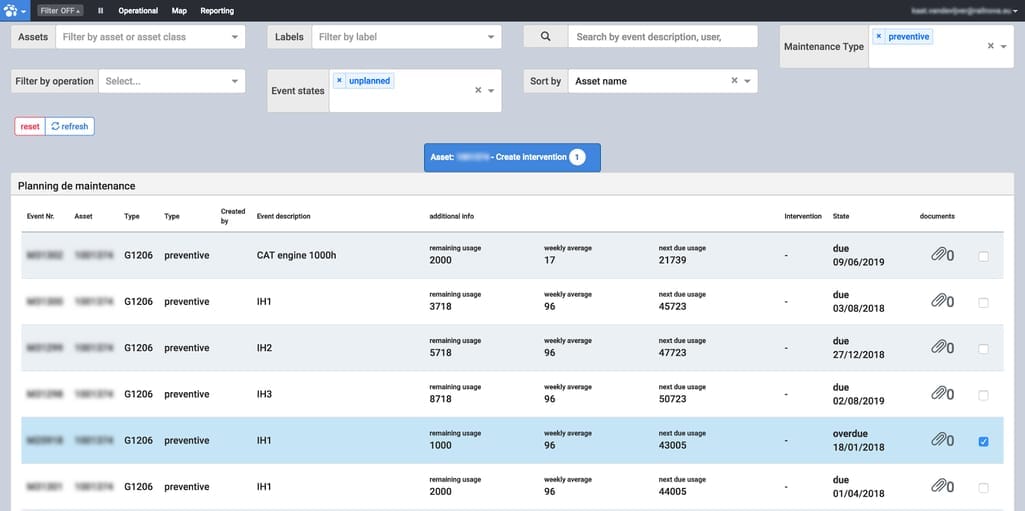

Repair scheduling

Preventive maintenance is about regular inspections and planned servicing. It’s important to schedule these activities and perform them on time to avoid breakdowns as much as possible. Software can help manage planning (so that the shipping process isn’t interrupted) and alert you when servicing or repairs are due.

Preventive maintenance dashboard. Source: Railnova

Some systems also have the functionality that supports staff scheduling, work order creation, parts inventory management, and so on – for those companies that handle asset maintenance themselves.

Predictive maintenance in rail

Predictive maintenance (PdM) is all about constant monitoring of equipment condition and performance, identifying unhealthy trends, and detecting possible upcoming failures. It allows you to precisely schedule repairs in advance on the basis of sophisticated analytics to minimize operational disruptions.

It requires a complicated, custom-built IoT infrastructure to collect equipment measurements and analyze them. To get the most complete and accurate picture, not only sensor measurements are used but also historic CMMS records and external data such as weather, geographical conditions, and so on.

Here’s an example of how it works. With 5,000 sensors located along its rail tracks, Union Pacific records about 16 million railcar bearing temperatures, 7 million wheel temperatures, 250,000 wheel impact measurements, and 100,000 bearing acoustic measurements in one day.

All these readings are transferred to its servers and analyzed for any immediate problems. In addition, even if no unhealthy conditions are detected, advanced machine learning (ML) algorithms meticulously scrutinize data to recognize patterns, identify potential faults, and generate actionable predictions.

Predictive maintenance based on IoT requires investment and accurate project planning. Maintenance specialists and engineers have to work closely with data science professionals to define which data is needed, how it can be obtained, and how it should be processed to deliver best results and address specific business needs.

Planning, reporting, and analytics

To optimize your operations, you need maximum visibility into all the aspects of your business. Having complete information at your fingertips, you can effectively plan your activities and identify opportunities for improvement.

Optimizing asset utilization

Software can give you the understanding of how your rolling stock is utilized as you’ll be able to monitor availability of every piece of equipment via convenient dashboards and customized tables. The scheduling functionality helps automate planning processes and improve asset utilization.

An optimal assignment schedule is created taking into account numerous factors such as actual transit times, shipping volume, planned maintenance activities, seasonality, and so on. Such a schedule will keep all your equipment busy and you’ll be able to control your fleet size.

Performance monitoring

As we said, it’s crucial to monitor how your fleet operates to understand its weaknesses and development potential. Specialized software can generate rail-specific reports and help you monitor KPIs that demonstrate your fleet performance, cycle times, sizing requirements, costs breakdown, utilization capacity, and much more. Data and business intelligence can help you discover improvement opportunities and make effective strategic decisions.

We’ve discussed some of the common features of rail fleet management platforms. Of course, there are solutions that offer a wider functionality scope including, for example, lease management or invoice auditing. So let’s look into what’s there on the market.

Rail fleet management software providers

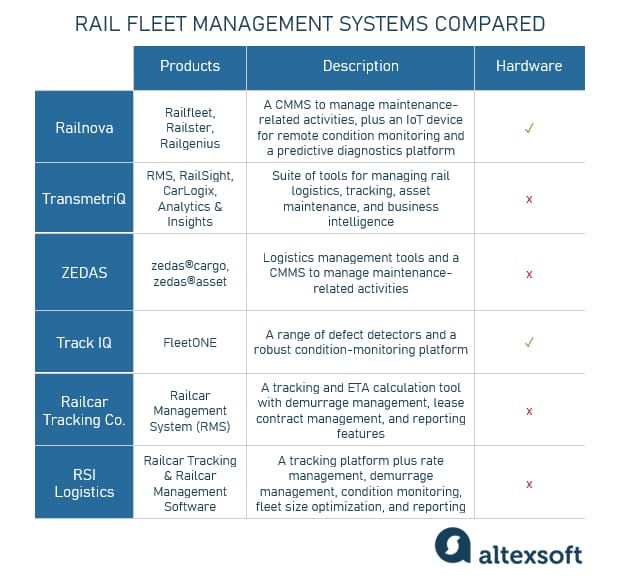

Even though there’s a lot of asset management solutions, it’s crucial to implement an industry-specific platform designed to process railway-related measurements and generate actionable reports. Please also note that we don’t promote any of the vendors but only provide you with an overview of available ready-made tools and their capabilities. And we’re starting with maintenance-focused solutions.

Rail fleet management platforms

Railnova: a robust CMMS plus a smart IoT device and a predictive analytics tool

Railnova is a tech company based in Brussels, Belgium, that offers comprehensive fleet management software and telematics solutions to different players in the rail industry, i.e., operators, lessors, maintainers, and manufacturers. Among its clients are such European giants as Eurotunnel, Alstom, Lineas, SNCF, and DB Cargo. Its suite of offerings includes three products that are easily integrated with each other.

Railfleet is a digital fleet management platform, essentially a CMMS, that allows drivers to easily report defects, service teams to see all the details on the reported issues and get work orders, and managers to schedule repairs and monitor performance, location, and important status updates.

Railster is an IoT device for remote monitoring and edge computing. It collects a variety of measurements, performs diagnostics, and sends data to cloud storage for further use.

Railgenius is a monitoring and predictive diagnostics platform with a rule engine and customized alert configuration.

Railgenius data inspector interface

TransmetriQ: powered by the industry data provider

TransmetriQ is a digital solutions provider backed by Railinc. That means it has deep industry expertise and access to data from 600+ North American railroads. Its suite of products includes a range of modular solutions for different needs.

- TransmetriQ RMS is the transportation management system designed for rail shippers. It helps manage documentation, ETAs, shipment statuses, reporting, and much more.

- The RailSight® Suite of Applications is the rail tracking service we mentioned above.

- CarLogix is the maintenance management platform for rail asset health monitoring, repair billing optimization, auditing, and so on.

- TransmetriQ Analytics & Insights is a suite of business intelligence applications that offer insights into various operational areas.

All of the products can be easily integrated with other (and some have open APIs for third-party connections as well).

ZEDAS: two solutions to manage logistics operations and maintenance activities

ZEDAS is another European company that offers digital solutions aimed at streamlining asset management and logistics management of rail transport. They work with many rail/transport businesses and industrial companies in such sectors as mining, oil, gas, chemicals, production engineering, and renewable energy. It has two main software products.

zedas®cargo is a multi-featured, specialized instrument that digitizes, synchronizes, and documents all processes related to shunting services, long-haul traffic, and port railway operations.

zedas®asset is a robust, railway-specific CMMS. It helps manage all maintenance-related processes such as creating work orders, logs, and reports; generating standard compliant documentation; planning personnel, material, and tasks; and even handling leasing contracts.

Track IQ: a rich suite of detectors and a diagnostics platform

Track IQ (acquired by Wabtec in 2015), headquartered in Australia, is an industry-recognized manufacturer and supplier of railway equipment, sensors, software, and services related to measuring operating conditions. It works with multiple freight, heavy haul, and passenger railways worldwide.

Track IQ’s wayside technology is now helping over 200 railroads detect unhealthy conditions and improve efficiency. Its extensive suite of products includes

- RailBAM (Bearing Acoustic Monitor) – an award-winning system that detects axle bearing defects;

- Wheel Condition Monitoring (WCM) – a wheel impact load detector and weigh-in-motion system that captures data for improving wheel life, bogie maintenance, and safety;

- Wheel Profile Monitor (WPM) – an advanced machine vision technology that uses cameras to capture detailed wheel images that are later processed to generate important wheel profile measurements;

- Brake Inspection Monitor (BIM) – another camera-based system that captures and analyses images to identify brake conditions;

- Full Vehicle Inspection System (FVIS) – a modular suite of imaging equipment that can inspect a big range of rolling stock components;

- Train Noise Monitor (TNM) – a technology that uses a high-precision microphone to record and assess noise levels of passing trains; and so on.

FVIS by Track IQ

All these wayside detectors are most efficient when integrated with a comprehensive fleet management solution that can analyze obtained measurements.

FleetONE is a multi-sensor trending database product that integrates a range of wayside monitoring equipment data into a single system (including third-party sensors) and enables efficient vehicle monitoring and data mining via key vehicle metrics.

It’s important to understand that FleetONE is a handy tool to consolidate and conveniently monitor all the condition-related information, including defining trends and generating failure predictions. However, it has to be integrated with an external maintenance management system such as SAP or IBM Maximo to control repair activities (e.g., work orders generation, staff scheduling, etc.).

FleetONE by TechIQ train summary dashboard

Railcar Tracking Company: more than fleet tracking

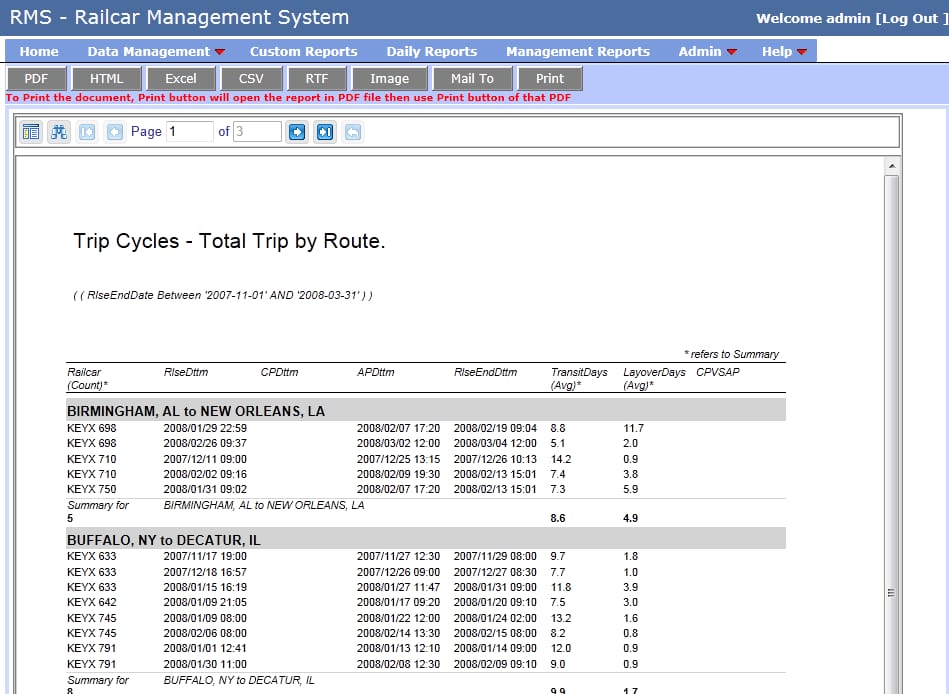

Railcar Management System (RMS) by Railcar Tracking Co. focuses on tracking rail shipments and calculating precise ETAs. To make it possible, it combines the information from over 550 railroads in North America.

Other features include demurrage and detention management and lease/sublease contract tracking. In addition, RMS offers an array of reports and KPI monitoring opportunities that help analyze asset utilization efficiency and identify bottlenecks and areas for improvement.

Trip Cycle report in RMS

RSI Logistics: all-in-one fleet management solution

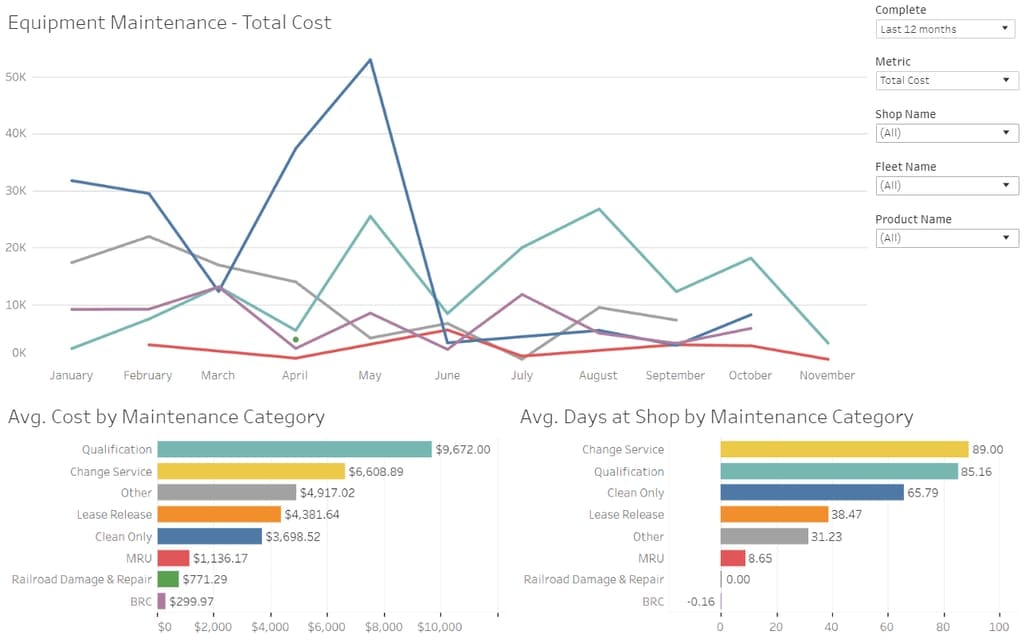

Railcar Tracking & Railcar Management Software by RSI Logistics is more of a one-stop-shop for fleet managers. This software not only enables asset tracking, but also supports rate management (contracts, tariffs, fuel charges, etc.), gives control over demurrage charges, monitors equipment health, helps optimize fleet size, and provides a wide array of reporting options.

Equipment maintenance dashboard. Source: RSI Logistics

Which rail fleet management software to choose?

The freight rail market is exceptionally diverse. Every company is different and has unique business requirements. Most likely, you already have some software to manage your fleet-related activities. So the first thing to do is review your current IT landscape, identify its weaknesses, and outline your needs.

It might turn out that you don’t need a new platform but only need to modernize a legacy system or just add another module to cover a poorly-managed workflow (just remember about building a seamless integration with your other systems to enable smooth data flow). As you might have noticed, there are many software products that are created on a modular basis so that customers have an opportunity to purchase only what they need.

If after your research you still consider adopting a completely new solution, you’ll have to decide whether you want to buy the ready-made one or build your own. Off-the-shelf products are typically cheaper and faster to implement, but custom development would deliver a comprehensive system perfectly tailored to your specific business needs. Besides, if you want to create a modern IoT infrastructure with advanced, ML-based analytics, it’s only possible with a bespoke solution.

Maria is a curious researcher, passionate about discovering how technologies change the world. She started her career in logistics but has dedicated the last five years to exploring travel tech, large travel businesses, and product management best practices.

Want to write an article for our blog? Read our requirements and guidelines to become a contributor.