Fuel is one of a fleet operator’s biggest pain points. Being the second largest expense category (after labor costs), fuel seems to be an everflowing source of stress and lost money. And it is -- if you don’t control it.

Fuel management is not a complex topic to dive into, if you’re already using a fleet management solution. This article will help you discover what other opportunities your software has in terms of fuel efficiency. And if you’re only considering getting or building an FMS, this will be your guide to the best features to ask your vendor about.

What is fuel management system and fuel economy

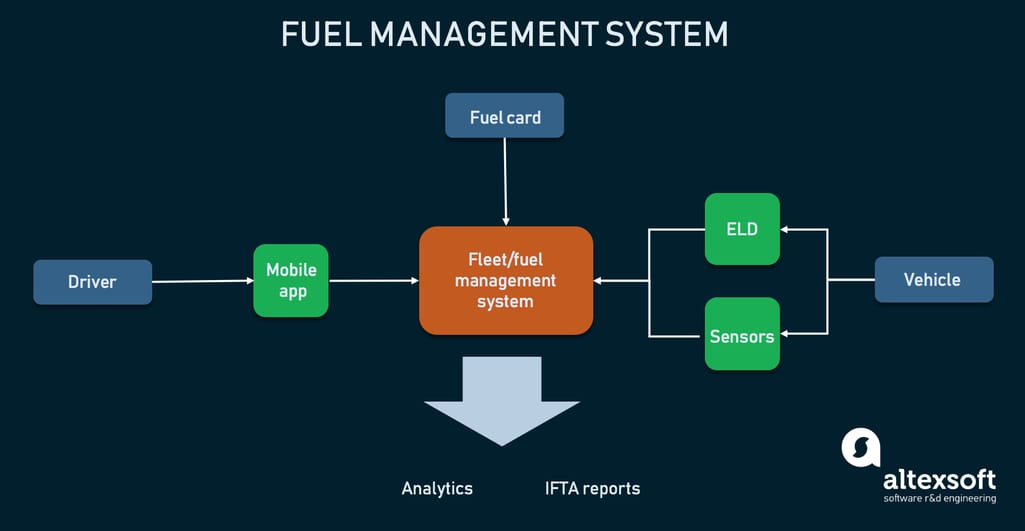

A fuel management system is a subdivision of a fleet management system that uses telematics-based tools and analytical software to capture fuel consumption data and improve fuel economy.

A fuel management system uses data from different sources to create comprehensive analytics

Fuel economy/efficiency in transportation is an indicator of how long a vehicle can travel on a unit of gas. In the US, it’s expressed as miles per gallon (MPG). There are many ways in which we can’t improve a vehicle’s fuel economy (the type of vehicle it is and the engine it uses or how old the engine is), but there are even more ways affecting fuel economy that we can control:

- Sensible driving behavior can boost fuel economy 10-40 percent and save up to $1.15 per gallon.

- Proper and timely vehicle maintenance can increase fuel economy 4 percent and save $0.11/gallon.

- Fuel variations (summer gas or ethanol-added gas) may improve fuel economy up to 4 percent.

But if you manage the fleet, fuel economy is just one of the tasks you’re concerned with. There’s also:

- Fuel cost management

- Internal and external fuel fraud

- Unnoticed fuel leakage

- Complex and time-consuming fuel reporting

How do fuel management tools help tackle these issues?

Problems that fuel management systems solve

Monitor fuel costs. They incorporate data about fuel transactions into analytics and learn what brands of fuel bring better economy, compare fuel usage across vehicles, break down fuel spend, and generally improve your fuel buying behavior.

Incorporate good driving habits. By collecting information about unnecessary speeding, harsh braking, and excessive engine idling, you can support efficient drivers with incentives and provide training for drivers who have inefficient driving habits.

Capture and prevent fuel theft and leakage. Fuel monitoring and anti-siphoning devices can update you on fuel amounts in trucks and on-site tanks and send alerts about fuel levels.

Calculate and report fuel taxes. Integrated with your vehicle’s GPS, a fuel management system can automatically calculate traveled distance and purchased fuel to help file your IFTA tax reports.

The ultimate benefit of fuel management systems is automation -- operations that used to be done manually in spreadsheets can happen automatically in the background, providing analytics for you to base your decisions on. Now, let’s cover the main opportunities and how they work.

Note: A larger portion of the article will cover fleet businesses that source fuel from regular gas stations. We will cover on-site fuel management opportunities in the next section.

Fuel logging and reporting

A fuel log is a record of the fuel purchase details of a specific fleet vehicle. It’s also the main information resource that enables fleet managers to review fuel costs and compile IFTA reports.

The most basic data that can be pulled from fuel logs are:

- Date and time of transaction

- Price per gallon

- Purchased gallons

- Odometer data at the time of transaction

- Location of a fueling station, etc.

All of this can calculate a vehicle’s MPG (miles per gallon), detect inefficiencies and suspicious transactions. Typically, there are several options for keeping a fuel log.

Fuel cards

If you operate a fleet of vehicles, you either heavily rely on fuel cards to pay for fuel or you’re at least familiar with them. Just to recap, fuel cards are plastic cards with a magnetic strip or an RFID chip that allow drivers to pay for gas at regular gas stations. To access terminals, drivers use a personal PIN, which authorizes the transaction and provides an admin in the office all its details.

As opposed to normal corporate credit cards, fuel cards offer a number of benefits: They allow you to avoid credit card fees, don’t have the risk of theft, provide fuel at a wholesale price, and, of course, save on administrative costs such as manual reconciliation of paper receipts. Fuel cards are used everywhere, except in the instances where the transportation company uses their own fueling facilities.

Integrated with the fuel managing software, fuel cards automatically log fuel information for the fleet manager to see in real-time or in timed reports.

Manual entry

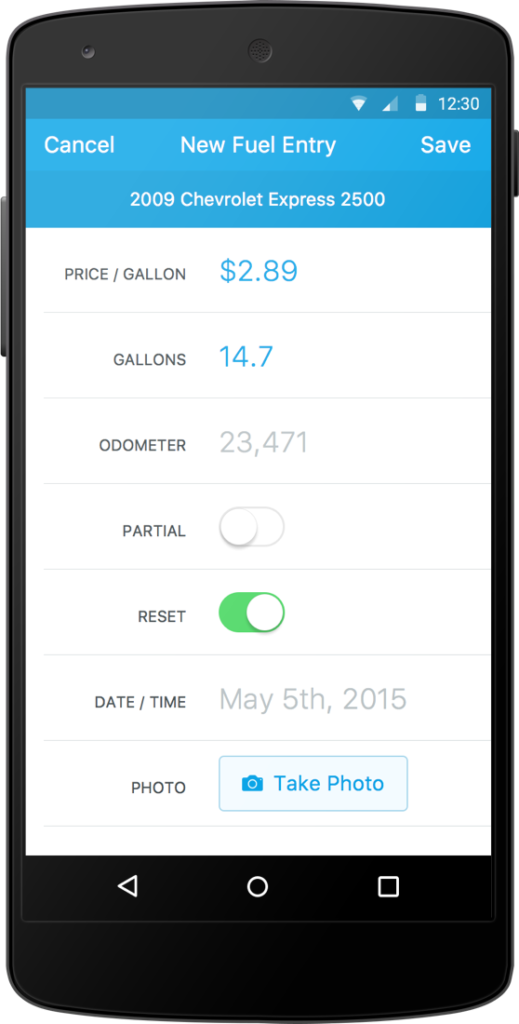

Driver apps often come with your fleet management software, but they can also be integrated from a third party. Used for a variety of tasks, driver apps are also handy to enter fill-ups on they go in a predefined form.

Pulled from telematic devices

Some fields of logs can be filled by data from tracking devices installed on the vehicle. You can integrate odometer sensors or GPS devices to collect data from machines rather than drivers and eliminate mistakes.

Fuel entry via Fleetio pulls odometer and date/time information automatically, while the rest can be entered by a driver Source: Fleetio

Fuel tax reporting

Data from fuel logs and fuel cards is also used for IFTA reporting. The International Fuel Tax Agreement (IFTA) is an agreement between 48 US states and 10 Canadian provinces that simplifies the reporting of fuel use by commercial motor carriers. Under IFTA, a carrier must report the fuel consumed and the distance traveled in each jurisdiction and pay motor fuel taxes. To automate this process, fuel reporting software can use data from fuel cards or your fuel logs.

Watch the IFTA reporting capabilities on GeoTab

Using fuel log data for analytics can be extremely helpful, but in some scenarios, it won’t give you the full picture. Let’s move to other opportunities for fuel optimization.

Driver behavior monitoring

Imagine you have two of the same vehicles traveling the same route at the same time of day. You would expect they should report the same fuel consumption. But one vehicle shows a greater MPG than the other one. Without additional data, you won’t be able to know what the problem is and be able to fix it. So, an ELD’s capabilities are used.

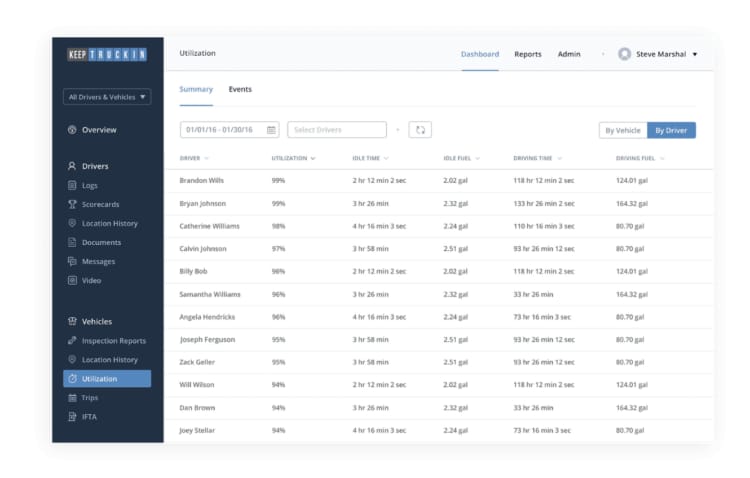

Commercial motor carriers in the US are required to have an electronic logging device (ELD) installed on their trucks to report their drivers' hours of service. But depending on a provider and in combination with analytical capabilities, ELD devices can be used to record a variety of data to improve safety and efficiency. ELDs communicate directly with a vehicle’s engine control unit (ECU), which allows for receiving information from the engine, brakes, and transmission sensors that ultimately show two main metrics of driver behavior: idling time and harsh events.

Idle time

By seeing the idling times of different drivers, you can incentivize the more effective drivers and find ways to solve the idling problem. For example, you can try investing in alternative climate control options and see if it helps drivers spend less time idling.

KeepTrucking allows you to filter by idle time and idle fuel usage to distinguish best and worst performing drivers Source: KeepTrucking

Harsh events

Usually employed with a gyroscope and accelerometer, ELDs can pull information about events like harsh turning, braking, or collision. By logging this data you can both coach drivers on safe driving and prevent future events by providing data about areas with dangerous turns to other drivers.

Fuel theft detection

In a 2015 survey, 53 percent of fleet operators said that they frequently noticed that fuel costs exceed projections. It’s unclear how much fuel is regularly stolen from carriers because fraud prevention technologies remain an uncharted territory for many businesses. But they shouldn’t be. Here are solutions for two of the most common fuel theft methods.

Fuel skimming detection

Fuel card skimming is the theft technique where a special device is attached to a payment terminal in a gas station to steal your fuel card information. There are various types of such devices. Sometimes they are just hidden cameras, in other instances, the keypads may be fake. But it’s often even more sophisticated when a thin stripe is hidden in a card slot to copy your card’s magnetic strip data.

The only prevention technique you can use is training your drivers on how to inspect the terminal for the signs of tampering. To detect the already stolen fuel card information, you can use GPS tracking capabilities of an ELD. For example, if the location of fuel card usage is different from the vehicle’s current location, the system will alert the agent to take action.

Siphoning detection

Siphoning is when fuel is removed from a company’s asset (fuel tank in the truck or the fuel storage tank on-site) and placed in a vehicle or container not belonging to the company. You can use ELD data to detect the irregularities after the case, but you won’t be able to learn when or by whom the fuel was syphoned -- you need a real-time telematics device for that. There are two popular options.

CAN bus. The vehicle CAN (controller area network) bus is a standard communication technology installed in most modern light vehicles and trucks. It allows an onboard computer to receive data from sensors installed in the fuel tank by a manufacturer. To send this information to your fuel management system, you need a GPS tracking device. Using the CAN bus sensor will save you installation costs and effort, but it’s been observed to have an error rate of up to 15 percent and doesn’t calculate the dead zones in the bottom and the upper parts of the tank, making it less reliable than other fuel sensing options.

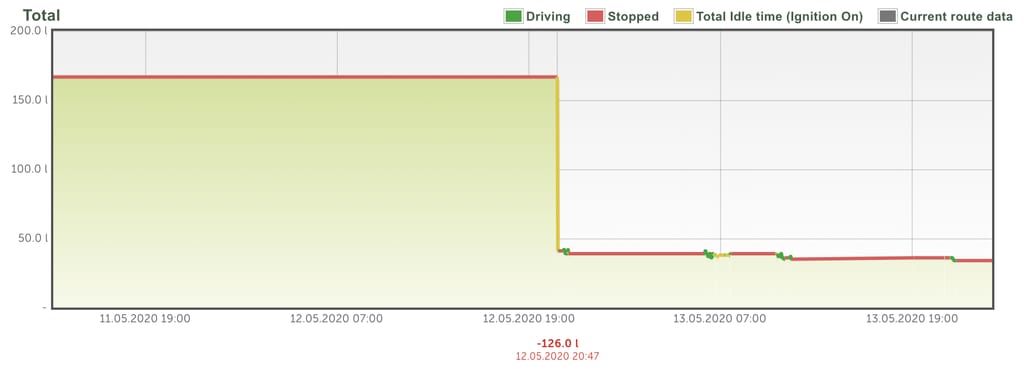

Fuel level sensor. A fuel level sensor is a device installed in a vehicle's fuel tank. Such sensors have an 1-2 percent error rate and can provide readings on fuel consumption, the dates and locations of refills, the drainage volumes, and fuel level volumes in certain periods of time.

The sharp decrease of the graph shows the possible drainage Source: MapOn

Whenever fuel loss takes place, the system will alert the fleet manager and the driver. Besides, the fluctuations in fuel consumption can show the idle time and be used in driver behavior analytics.

Predictive maintenance

There's strong evidence that maintenance of trucks increases fuel economy by 5-10 percent. When studying this subject, the North American Council for Freight Efficiency described ten components where proper maintenance impacts the fuel economy the most:

- Lubricants/engine oil

- Intake/exhaust system and diesel particulate filters

- Engine cooling

- Air compressors

- Wheel alignment

- Tires

- Fuel filter systems

- Aerodynamic devices

- Electrical systems

- Air conditioning

Typically, fleet operating companies use preventive maintenance where oil, brakes, and fluids are changed on schedule, whether they need it or not. The modern, telematics-based approach is shifting towards predictive maintenance -- data from sensors and tracking technology is used to constantly update schedules and never fix what doesn’t need fixing.

Requiring major investments from IT specialists, such solutions are custom-built rather than purchased off the shelf. If you want to learn more about the infrastructure and implementation, use the links above.

Fuel storage monitoring

Larger fleet management companies often choose to purchase fuel in bulk and store it on-site, making it always available and at a cheaper bulk price. This saves time and money as you no longer need to calculate and monitor fuel costs. But a tradeoff is that now you need to monitor homebased fueling stations and control who uses the facility and how much fuel they’re dispensing.

Here, a different fuel control system is needed. There are typically three core elements to it.

- Controller

- Fueling dispensers

- Fuel management software

Here’s how it works.

- A driver and a vehicle have ID tags that are entered into the controller -- a user-facing terminal, the heart of the fuel management system.

- Based on the data from the fuel management software, a controller allocates a specific volume of fuel to be distributed to the vehicle.

- A driver scans a vehicle tag with a fuel dispenser, and if the tag is correct, the nozzle automatically opens and starts dispensing fuel.

- It then automatically stops.

This system allows prevention of all types of fuel theft from the facility, so only the correct volume of fuel can go to the correct vehicle. However, this is just the tip of the monitoring iceberg as you can implement any number of sensors you wish to control not only the dispensing of fuel, but also its delivery and quality when stored.

The extended ecosystem of on-site fuel management tools Source: Banlaw

How to approach fuel management integration

Now that you know what fuel economy opportunities there are, let’s recap three levels of fuel management adoption.

1. Simplified fuel logging and reporting

Most popular fleet management system vendors like Samsara, Fleetio, or Geotab already can extract data from fuel cards and driver mobile apps for your logs and IFTA reports. If you want to increase operational efficiency and monitor costs with minimal analytical capabilities, this is your choice.

2. ELD integration without real-time monitoring

Consider getting an ELD device that can tap into the hidden potential of your vehicles. If you want to receive reports of driver behavior but don’t care about real-time connection, you can get an ELD that can transfer data once a period to a USB.

3. ELD with telematics capabilities and vehicle sensors

To use the collected data in real time, set up alerts, and apply predictive maintenance, you will need a telematics-powered infrastructure of hardware and software. If you have the budget, consider the option of custom development, where you will be able to set up complex integrations between systems and devices, establish effective data pipelines for your personalized business intelligence reports, and run the business without the limitations of ready-made systems.

Maryna is a passionate writer with a talent for simplifying complex topics for readers of all backgrounds. With 7 years of experience writing about travel technology, she is well-versed in the field. Outside of her professional writing, she enjoys reading, video games, and fashion.

Want to write an article for our blog? Read our requirements and guidelines to become a contributor.